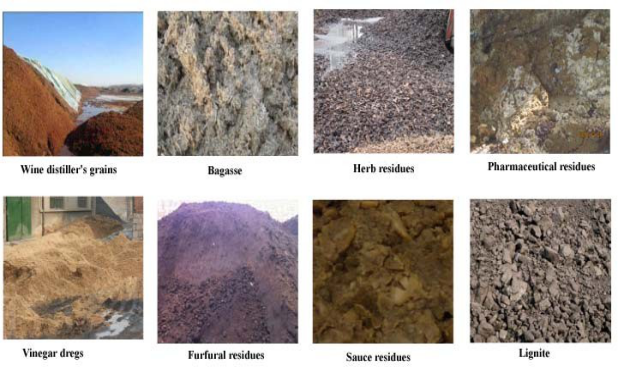

Energy and environment are two major themes of current society, with increasingly serious of energy crisis and environmental problems, world pay more attention to new energy sources exploration and protecting the environment protection. China has developed light industry, the industry accounts for 30% of gross industrial output value, a large amount of industrial by-product will be generated during pretreatment, production and processing of light industry. Such as distiller's grains, vinegar residue, dregs of medicine, sauce residue, bagasse, coffee residue and so on. According to statistics, China's annual output of industrial biomass waste is about 0.3 billion tons, among them, amount of distiller's grains is more than 30 million tons, amount of bagasse is more than 30 million tons, amount of medicine residue is more than 12 million tons, amount of furfural residue is more than 4.5milion tons, amount of vinegar dregs is more than 2 million tons. Industrial biomass has following features, such as high yield, concentrated emission, rich cellulose and hemicellulose, high calorific value of dry base (3000-4000 kcal/kg) and other resource characteristics,they are important Biomass resources and energy; on the other hand, because of their high water content (more than 60 wt.%), they are rich in organic matter with high nitrogen content, perishable, odor and other characteristics, light industry has large demand for steam in China,a lot of natural gas or coal fuel are burnt for every year, this inevitably lead to dust pollution and CO2 emissions. Therefore. Steam conversion of industrial biomass waste during production process is a major energy-saving emission reduction technology for light industry, it represents important demand for green development.