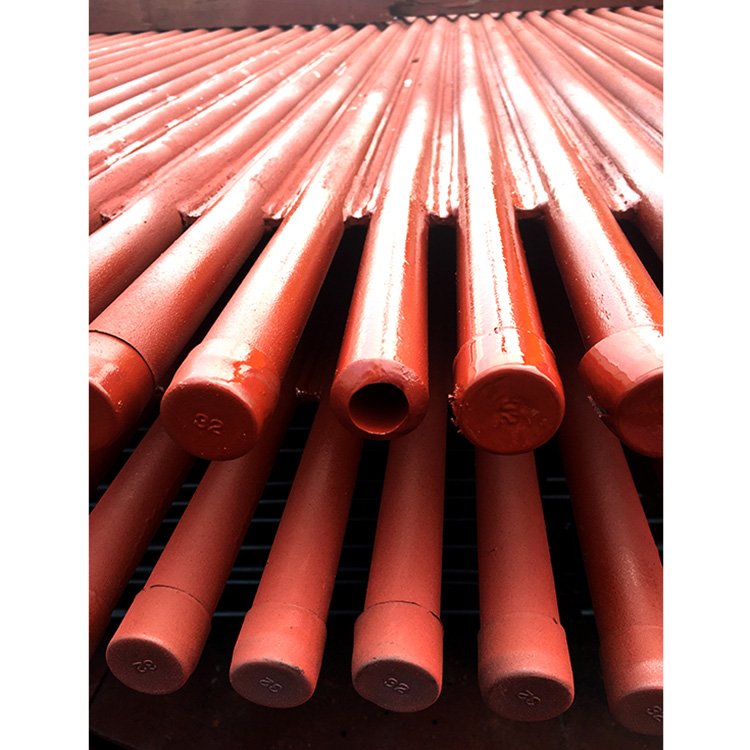

Carbon steel membrane water wall panel GTAW welding ISO9001 250MW fossil fuel power station

Image of this Carbon steel membrane water wall panel GTAW welding ISO9001 250MW fossil fuel power station

Dehai Boiler is a manufacturer for A-class boiler (power plant boiler, industrial boiler, HRSG, waste-to-energy boiler, biomass boiler etc.) and correlated pressure parts. We supply boiler design, fabrication, installation, repair and maintenance.

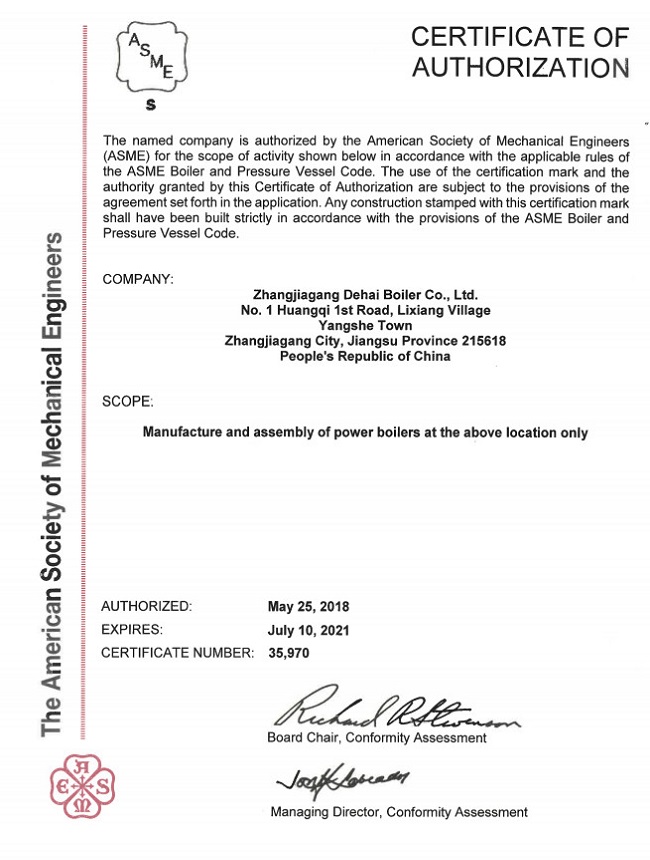

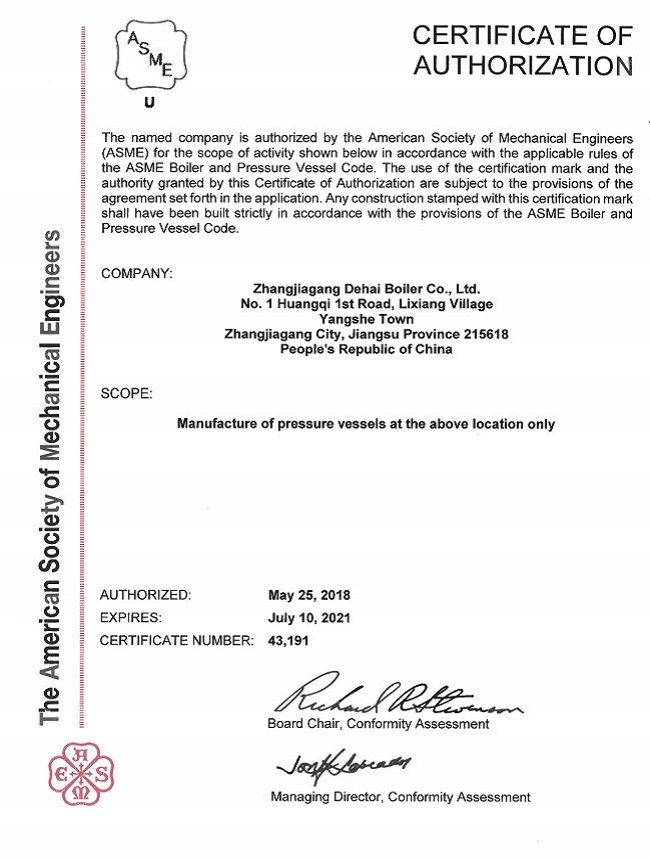

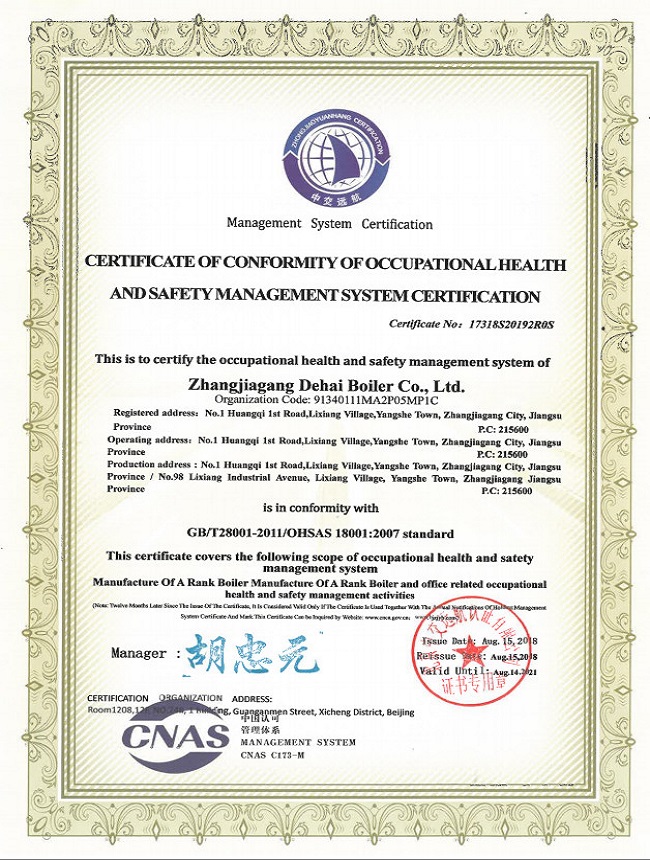

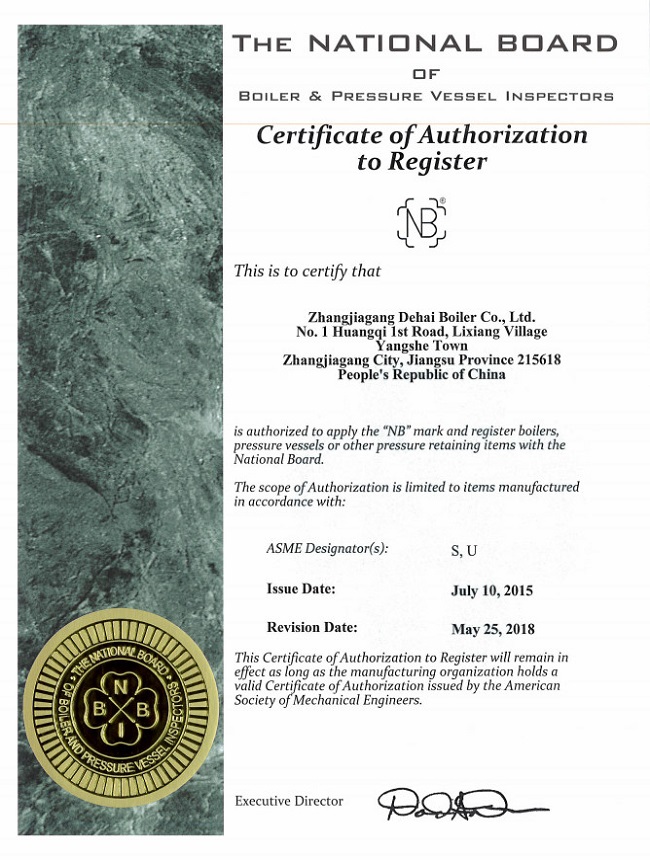

Dehai has ISO9001:2008 certificate issued by France AFAQ-EAQA Ltd, A-class boiler manufacturing license, ASME “S” and ”U” stamp authorized certificates.

In view of effective manage system and superior product quality, we’re the qualified supplier for many famous domestic and overseas boiler factories and energy companies. We supply for Dongfang Boiler, Harbin Boiler, Hangzhou Boiler, Amec Foster Wheeler, etc.

“High quality for survival and perfect service for development” is our business philosophy, we care customers’ demand and supply customers with constantly improving work and product quality to create Dehai brand.

Who is Dehai?

Manufacturer with 20 years’ experiences.

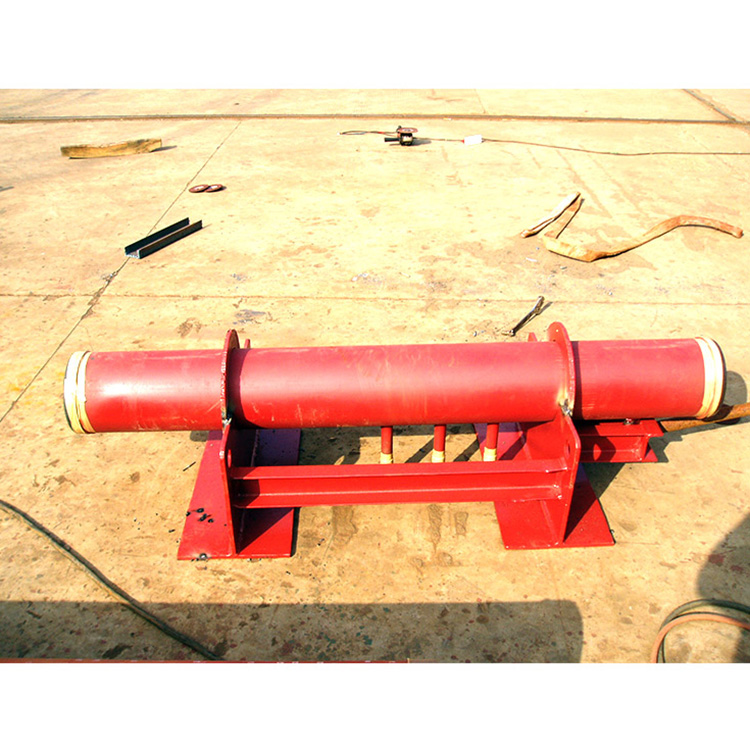

Specialize in producing boilers and pressure parts.

Products have been exported to over 36 countries and regions.

One modern standard workshop covers 48,000 ㎡.

Cover an area of more than 80,000 ㎡.

Who we work with?

Certificate

Our Service of this Customized stainless superheater TIG butt welding ASME ISO9001 fabrication for high pressure power plant or industrial boiler

1. The design and fabrication are in compliance with the latest related standards and strictly carried out according to ISO 9001 system, so that it can satisfy client’s requirement of product traceability.

2. Welcome purchasers or their authorized persons to our workshop at any time to do random inspection and supervision during fabrication. And we will support them actively.

3. During the equipment installation, we can assign professionals to guide at site and participate in the commissioning.

4. In case the problem occurs during running and shall be handled by us at site, we will reach there immediately after receiving notification from the purchaser.

5. We will provide the required spare parts timely with favorable price.

6. We sell products in the faith of “To take clients’ satisfaction as the standard” and provide the lifetime service for our delivered products.

FAQ of this Customized stainless superheater TIG butt welding ASME ISO9001 fabrication for high pressure power plant or industrial boiler

where is delivery port?

We are 100 kilometers away from Shanghai port. Most goods are shipped at Shanghai port.

But customers can specify the delivery port or choose other transportation modes.

How about the package?

Each layer is separated by plywood, been fixed by straps and placed into iron frame or iron box, then covered by waterproof cloth.

Packaging method can be customized as requested.