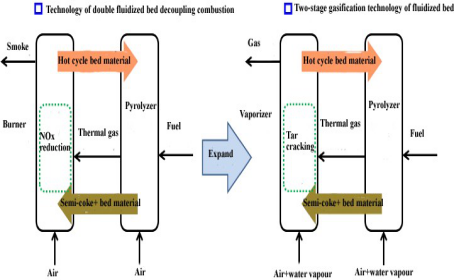

On the basis of double fluidized bed decoupling combustion technology, the principle of double

fluidized bed heat transfer technology is extended to fuel gasification by institute of process engineering of Chinese Academy of Sciences, two-stage gasification technology has been developed for high moisture fuel and low tar production. Please check figure 10,the technology mainly includes riser gasifier, fluidized bed pyrolysis device and return feeder. The fuel is firstly added to the pyrolysis unit and mixed with high temperature cycle bed material from the gasifier, temperature rapidly rise, the occurrence of drying and pyrolysis reactions generate pyrolysis semi-coke and pyrolysis gas products for enter bottom of the gasifier, they conduct gasification reaction with the air and water vapor. Under the action of high temperature semi-coke and circulating bed material, tar of pyrolysis gas products react thermal cracking and catalytic cracking, and it is transformed into gas, tar content of outlet gas is greatly decreased, which need not additional gas purification device, technological advantage is no tar and phenol water generation.

Figure 10: Ideas and principles of technological development

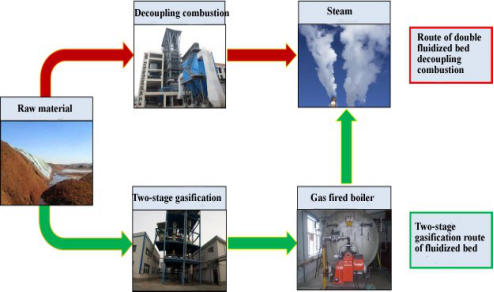

Figure 11: Two-stage gasification technologies comparison of double fluidized bed decoupling combustion and fluidized bed

Figure 11 indicates that two-stage gasification technologies comparison of double fluidized bed decoupling combustion and fluidized bed. As for double fluidized bed decoupling combustion

The raw material is directly burned to produce steam after pretreatment, and the technical route is simple and efficient; As for two-stage gasification of fluidized bed, the technology is suitable for enterprises that have gas boilers or other boilers, and after pretreatment, the raw material is gasified for producing low tar gas, it can be burned in a boiled boiler, it can replace some boiler fuel (such as natural gas) and reduce NOx emissions.

At present, two-stage gasification technologies has been applied in Henan Zhongjing Wanxi Pharmaceutical Co., Ltd and Shandong Buchang Pharmaceutical Co., Ltd. Following energy utilization projects of Chinese medicine slag are respectively established and operated, projects can respectively handle Chinese medicine slag 10000 tons/year and 50000 tons/year. thus, harmless and resource utilization has been achieved.

Table of main application companies

Company | Applied technology | Start stop time of application | Application situation |

Henan Zhongjing Wanxi Pharmaceutical Co., Ltd | 10000 Tons/Year, two-stage gasification project of traditional Chinese medicine slag fluidized bed | May 2014-Now | Good |

Shandong Buchang Pharmaceutical Co., Ltd | 50000 Tons/Year, two-stage gasification project of traditional Chinese medicine slag fluidized bed | April 2016-Now | Good |

Two-stage gasification for Chinese medicine slag 10000tons/year

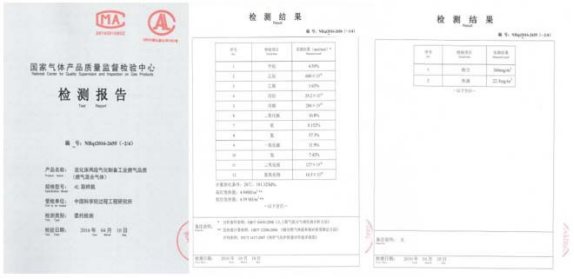

The project has been established in Henan Zhongjing Wanxi Pharmaceutical Co., Ltd. the project was established in 2013 and it is finished in January 2014, the project has been smoothly operated from May 2014 to now, manufactured gas can replace natural gas of gas boiler. Figure 13 is gas detection report (national gas product quality supervision and testing center) of two-stage gasification devices of Chinese medicine slag fluidized bed at the exit, detection result: lower heating value is 4.59 MJ/Nm3 (1100 kcal/Nm3), dust content is 366 mg/Nm3 in gas, tar content is 22.3 mg/Nm3.

Figure 12: Two-stage gasification project of 10000 tons/year Chinese medicine slag fluidized bed

Figure 13: Gas detection report of two-stage gasification demonstration project of 10000 tons/year Chinese medicine slag

Benefits of energy saving and emission reduction for the past three years

Year | 2015 | 2016 | 2017 | Total |

Handling capacity of herb residues (10000 Tons) | 1.1 | 1.3 | 0.7 | 3.1 |

Steam output (10000 Tons) | 1.4 | 1.7 | 0.9 | 4.0 |

Steam output value (10000 Yuan) | 392 | 476 | 252 | 1120 |

Profit (10000 Yuan) | 280 | 340 | 160 | 780 |

Handling cost of saving traditional Chinese medicine residue | 55 | 65 | 35 | 155 |

CO2 emission reduction (10000 Tons) | 0.39 | 0.48 | 0.26 | 1.13 |

The project totally handled 31000 tons of wine distiller's grain and produced 40000 tons of steam between 2015 and 2017, according to steam production cost calculation of natural gas combustion, the cost of steam per ton is about 280 Yuan, net output value of steam is 11.2 million Yuan and net profit is 0.78 million Yuan, handling cost of saving Chinese medicine slag is 1.55 million Yuan. Meanwhile, cumulative emission reduction of carbon dioxide is 11300 tons for the past three years,

4300 tons coal or 2.58 million m3 natural gas are saved.

(2)50000 tons/year, two-stage gasification of fluidized bed of Chinese medicine residue

The project has been established by Shabdong Buchang Pharmaceuticals Co.,Ltd, it has been finished by many engineering and machinery companies, the project has been finished in May 2016, the project is successfully at one time in April 2016, similar operating characteristics and energy-saving emission reduction effect just like engineering of Zhongjing Wanxi Pharmaceutical Company has been achieved.

Figure 14: 50000 tons/year two-phase gasification project of fluidized bed with Chinese herb residue