high efficient cement kiln waste heat boiler with best price

Cement kiln waste heat boiler The new-type dry method cement production pure low-temperature waste heat power generation technology can effectively reduce the energy consumption during the cement production process because it can convert the heat energy inside the waste gas into electric energy, and has remarkable energy-saving effect. At the same time, the temperature of exhaust gas is reduced if discharged through the waste heat boiler, Central heating for hotel bathroom cement kiln waste heat steam boiler which can effectively reduce the thermal pollution of cement production to the environment and has remarkable environmental protection effect. waste heat steam boiler The low-temperature waste heat power generation technology in cement kilns will surely have broad application prospects.

Among them, the steam-hot water flash evaporation combined power generation can make the best use of medium and low temperature waste heat. Boiler Steam Drum The technology mainly uses the 200℃-500℃ low temperature waste gas as heat sources to produce superheated steam and a certain amount of saturated water through a waste heat boiler, and uses a flash evaporation system to produce saturated steam which the conventional power generation systems fail to utilize to work together with superheated steam for power generation, hotel bathroom steam boiler thus increasing the power of waste heat power generation. Cement kiln waste heat boiler The system is reliable in technology, simple and convenient in operation.

Technical features

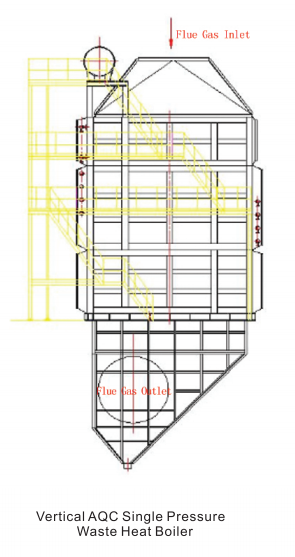

Characteristics of AQC Waste Heat Boiler

The boiler adopts the module assembly structure and the expansion seal is reliable.

The wear-resistant fin tubes are used to ensure the service life of boiler pressure elements.

The unique flash evaporation technology reduces the boiler outlet temperature to below 90℃.

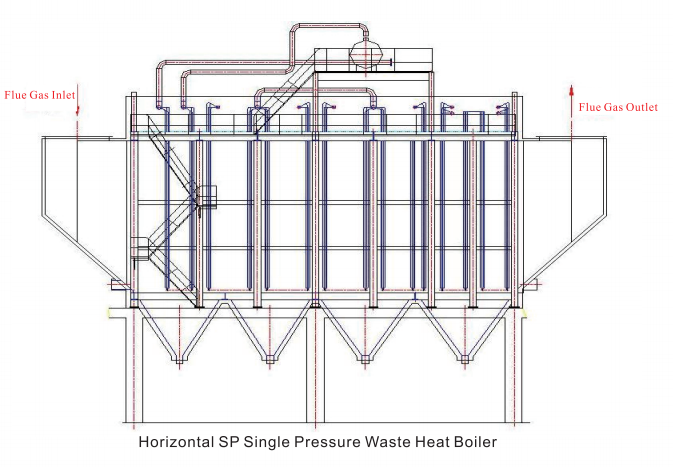

Characteristics of SP Waste Heat Boiler

The heating surface pipes and headers adopt a special connection structure to reduce the impact under mechanical vibration.

The mechanical vibration cleaning mode is adopted, and the continuous ash cleaning mode has little impact on the system operation.

A sealed scraper dust extractor is provided, which greatly reduces the quantity of tail dust.

Cement Kiln Single Pressure Series Waste Heat Boiler

Cement production line capacity t/d | 1000 | 2500 | 5000 | 10000 | |

Boiler inlet flue gas quantity (Nm3/h) | AQC | 60000 | 88000 | 243000 | 472000 |

SP | 76000 | 170000 | 328000 | 612000 | |

Boiler inlet flue gas temperature (℃) | AQC | 370 | 360 | 380 | 390 |

SP | 360 | 320~360 | 330 | 330 | |

Rated Evaporation Capacity(t/h) | AQC | 5.8 | 7.25 | 24 | 50 |

SP | 7.5 | 10~15.8 | 20~24.6 | 35.5 | |

Rated Steam Pressure (MPa) | AQC | 1.25 | 1.25 | 1.25 | 1.25 |

SP | 1.25 | 1.25 | 1.25 | 1.25 | |

Rated Steam Temperature (℃) | AQC | 340 | 330 | 350 | 360 |

SP | 340 | 300~340 | 310 | 310 | |

Boiler Type | AQC | Vertical | Vertical | Vertical | Vertical |

SP | Vertical | Vertical, Horizontal | Vertical, Horizontal | Vertical | |

Cement Kiln Double Pressure Series Waste Heat Boiler

Cement production line capacity t/d | 2500 | 3500 | 5000 | |

Boiler inlet flue gas quantity Nm3/h | AQC | 96800 | 142000 | 192000 |

SP | 173000 | 241000 | 369000 | |

Boiler inlet flue gas temperature ℃ | AQC | 380 | 420 | 395 |

SP | 365 | 360 | 355 | |

Rated Evaporation Capacity t/h | AQC | 2/9.6 | 3/17 | 3.2/21.3 |

SP | 4.2/16.2 | 5.3/23 | 10.5/32 | |

Rated Steam Pressure MPa | AQC | 0.2/2.4 | 0.2/2.4 | 0.2/2.4 |

SP | 0.2/2.4 | 0.2/2.4 | 0.2/2.4 | |

Rated Steam Temperature ℃ | AQC | 160 / Saturation | 160 / Saturation | 160 / Saturation |

SP | 160/250 | 160/250 | 160/250 | |

Boiler Type | AQC | Vertical | Vertical | Vertical |

SP | Vertical | Vertical | Vertical | |

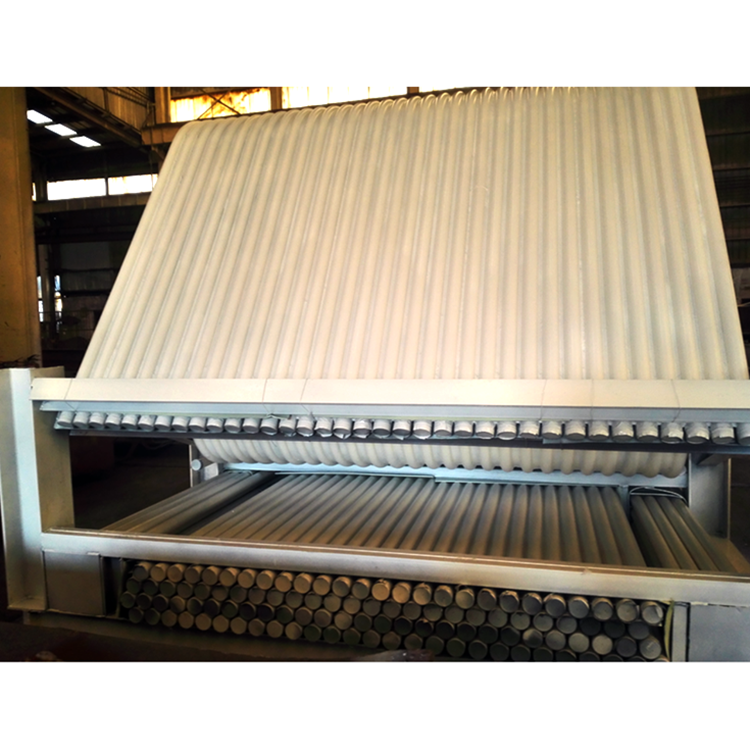

Image of this high efficient cement kiln waste heat boiler with best price

Dehai Boiler is a manufacturer for A-class boiler (power plant boiler, industrial boiler, HRSG, waste-to-energy boiler, biomass boiler etc.) and correlated pressure parts. We supply boiler design, fabrication, installation, repair and maintenance.

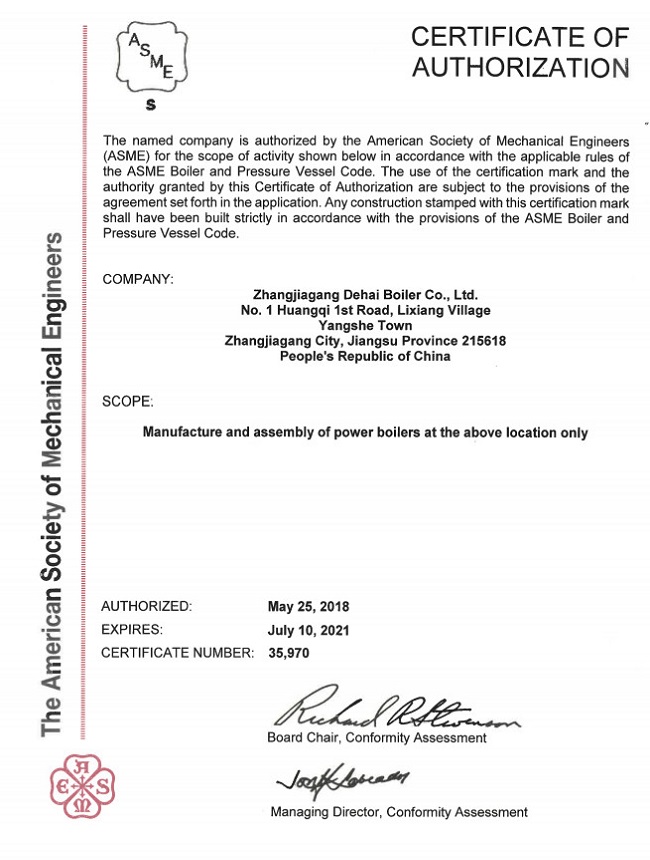

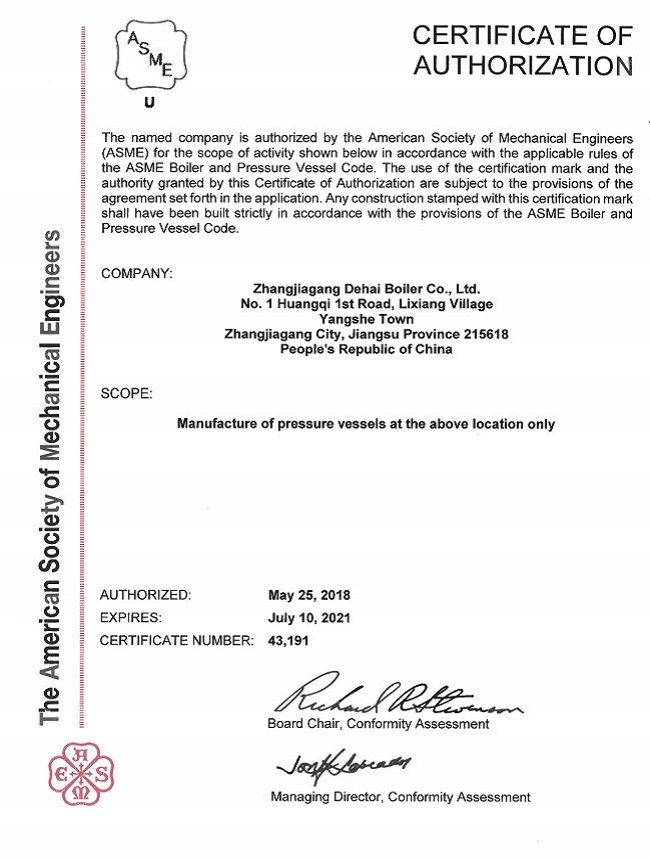

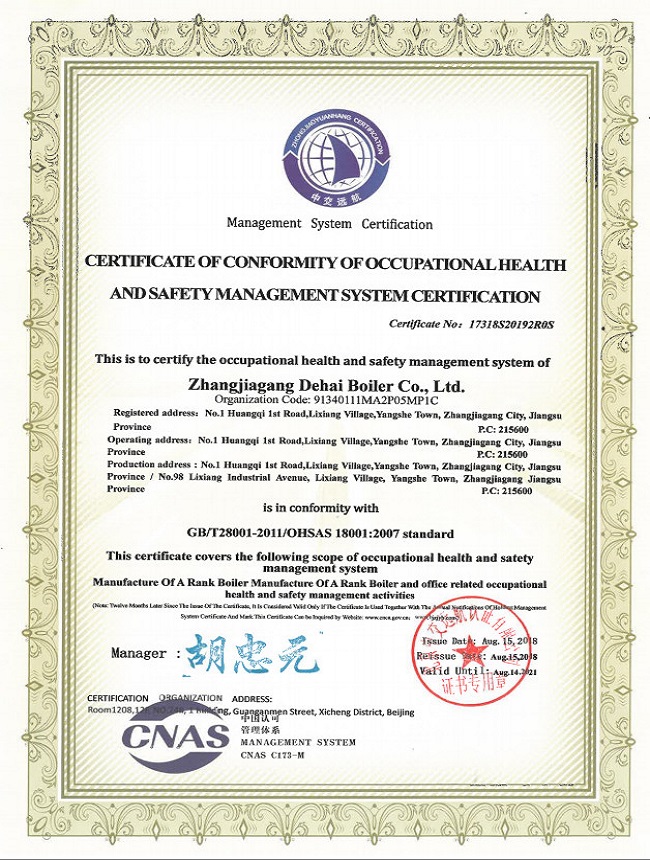

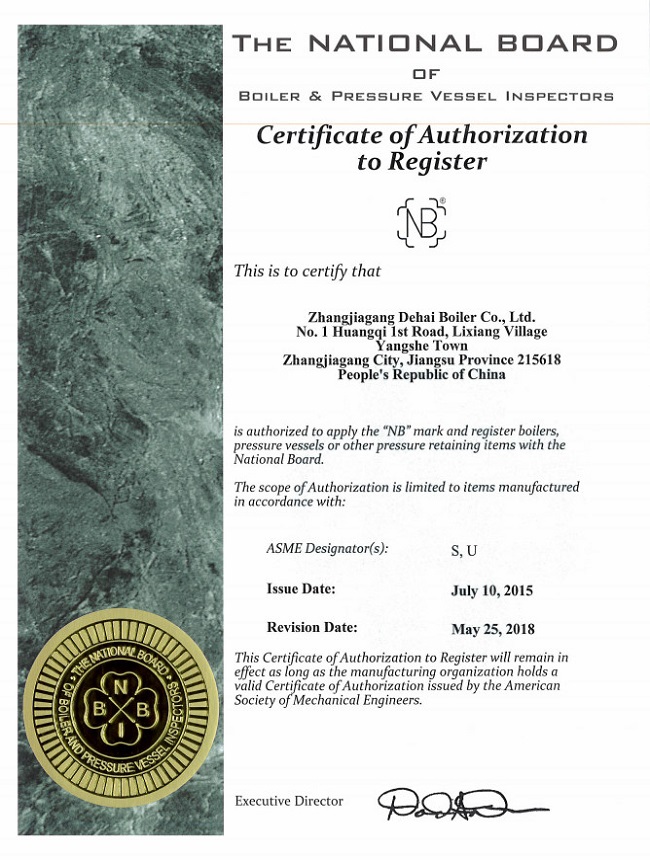

Dehai has ISO9001:2008 certificate issued by France AFAQ-EAQA Ltd, A-class boiler manufacturing license, ASME “S” and ”U” stamp authorized certificates.

In view of effective manage system and superior product quality, we’re the qualified supplier for many famous domestic and overseas boiler factories and energy companies. We supply for Dongfang Boiler, Harbin Boiler, Hangzhou Boiler, Amec Foster Wheeler, etc.

“High quality for survival and perfect service for development” is our business philosophy, we care customers’ demand and supply customers with constantly improving work and product quality to create Dehai brand.

Who is Dehai?

Manufacturer with 20 years’ experiences.

Specialize in producing boilers and pressure parts.

Products have been exported to over 36 countries and regions.

One modern standard workshop covers 48,000 ㎡.

Cover an area of more than 80,000 ㎡.

Who we work with?

Certificate

Our Service of this Customized stainless superheater TIG butt welding ASME ISO9001 fabrication for high pressure power plant or industrial boiler

1. The design and fabrication are in compliance with the latest related standards and strictly carried out according to ISO 9001 system, so that it can satisfy client’s requirement of product traceability.

2. Welcome purchasers or their authorized persons to our workshop at any time to do random inspection and supervision during fabrication. And we will support them actively.

3. During the equipment installation, we can assign professionals to guide at site and participate in the commissioning.

4. In case the problem occurs during running and shall be handled by us at site, we will reach there immediately after receiving notification from the purchaser.

5. We will provide the required spare parts timely with favorable price.

6. We sell products in the faith of “To take clients’ satisfaction as the standard” and provide the lifetime service for our delivered products.

FAQ of this Customized stainless superheater TIG butt welding ASME ISO9001 fabrication for high pressure power plant or industrial boiler

where is delivery port?

We are 100 kilometers away from Shanghai port. Most goods are shipped at Shanghai port.

But customers can specify the delivery port or choose other transportation modes.

How about the package?

Each layer is separated by plywood, been fixed by straps and placed into iron frame or iron box, then covered by waterproof cloth.

Packaging method can be customized as requested.